What you need to do before using a pellet machine?

Add lubricating oil

Before using pellet machine for the first time, you need to add lubricating oil to the gearbox, roller and shaft.

Every time before using pellet machine, make sure there are enough lubricating oil in each running part.

For each part, the lubricating period is different. You need to lubricate the roller every 4 hours, main shaft every 8 hours, and gearbox every 1 year (the first time is 6 months).

Check the Flat die and roller

Before starting the machine, you need check the flat die and roller. Make sure there is no foreign matters blocking them, and no loose in the fastening parts.

Check the abrasion of roller and die. The working life of flat die and roller is 300-500h under normal condition, and you can switch to the other side of flat die when it wears out.

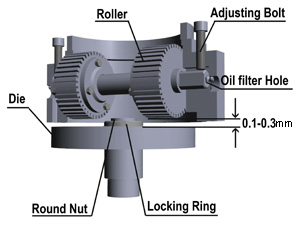

Adjust the clearance of flat die and roller

The clearance between roller and die determines the pelletizing effect. You must adjust it according to the materials you process. The best clearance is between 0.1mm and 0.3mm. If it is over 0.3mm, the material bed will be too thick and pellet production will be less. If the it is less than 0.1mm, the abrasion of roller and die will increase and shorten the working life.

How to adjust the clearance of flat die and roller

For roller-turned type: before feeding materials, loosen the lock bolt. Screw the adjusting nut clockwise to the end, then screw it towards the other side for 15°-30°. Finally, fasten the lock bolt.

For die-turned type: start the machine, feed a few materials, then adjust the adjusting bolt. When the roller start to run driven by the flat die, you can continue to feed materials and adjust the tightness of adjust bolt according to the pelletizing effect.

Flat die first grinding

Before first use, you need grind the flat die with oil mixture.

The oil mixture is composed of 20% fine sand, 65% biomass materials(like sawdust), 15% waste engine oil. The quantity of oil mixture is 10% of the pellets you pellet mill can produce every hour.

First, put a container under the outlet of pellet mill to collect the oil mixture for cycle use. Then, start the machine and feed the oil mixture to the machine. Don’t fill the bin too full. When the oil mixture passes through the hopper, it grinding effect is reached. The grinding process takes 40-60 minutes.

Besides, you can make the request that we grind it before delivery.

Pellet Machine preheat

Every time before making pellets, you need feed oil mixture repeatedly until the flat die temperature reaches up to 50 ℃. Then you can feed materials. In the beginning, pellets have some cracks on them. After 5 minutes, the machine temperature will go up to 80-100℃, then it can make pellets normally.

The oil mixture for pellet mill preheat contains 3-5kg raw materials and 10% waste engine oil.

Steps:Put a container under the outlet of pellet mill so that you can reuse the oil mixture. Start the machine and feed oil mixture to it. Don’t fill the bin too full. After a few minutes, there will be water vapor at the hopper. This means the machine start to heat up. When the produced pellets are hard enough, you can feed raw materials to make pellets.

Check the tightness of each connecting part

Before starting up, make sure the cap bolts at the ends of roller is tight, in case it fall off and cause damage to the roller. Then check other parts of the pellet machine completely to remove any loose part.

Ensure safety protection

Check if there is any power leakage in electric motor, electric cabinet and wires. Make sure the protective cover works normally. Keep the ground dry so as to minimize the risk of power leakage.

Check the rotating direction

For the first time use, please check whether the rotating direction is consistent with the indicative sign on the machine. If not, please adjust the drive engine. If it is normal, you need first switch on the circuit breaker, then press the start button.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!