wood pellet mill

The small wood pellet mill is GEMCO’s latest product. It adopts the latest advanced technology and has won both CE and ISO9000 certificates. GEMCO expert team has improved its structure and working efficiency to ensure its smooth running. The wood pellets output capacity of this residential wood pellets making machine is large enough for individual use. It is widely used on farm or at home, as it can meet the capacity needs and can be moved easily. This household wood pellet mill has 3 different driving forces: electric engine, diesel engine and PTO. You can choose the driving engine according to your own special favor.

Technical Data of Small Wood Pellet Mill

| Type | Power |

Pellet’s Diameter (mm) |

Capacity (kg/h) |

Weight (kg) |

Dimension(mm) |

|---|---|---|---|---|---|

| ZLMG420 (electric engine) | 37kw | 6, 8, 10 | 400-600 | 1100 | 1630*620*1400 |

| ZLMG420A (diesel engine) |

46kw (62hp) |

6, 8, 10 | 400-600 | 1200 | 2590*660*1400 |

| ZLMG420P (PTO) | 37-48kW | 6, 8, 10 | 400-600 | 700 | 1500*850*1400 |

Household Wood Pellet Mill Working Theory

Just like other household pellet mills in GEMCO machinery, this small wood pellet mill is also flat die designed, which means the die in the pellet mill is horizontal with a series of rollers above it. For this wood pellet mill for home use, when making pellets, its flat die is stationary while the two rollers rotate to push the raw material evenly on the flat die and meanwhile compress them into the holes in the die to form pellets. In this pelletizing process, pressure and friction are used to increase the temperature of the wood materials in the wood pellet maker, which in turn allows the lignum to soften and the wood fibers to be reshaped into pellets. And after the wood pellets leave the pellet extruder, they are air-cooled, the lignums solidify, and the pellet is formed. And a series of knives fixed on the main axis will cut the emerged pellets on the other side of the flat die immediately to make sure that the pellets have the same length. And the length can be changed by adjusting the position of the knives. Here is the detailed steps of how to make wood pellets both at home and in industry.

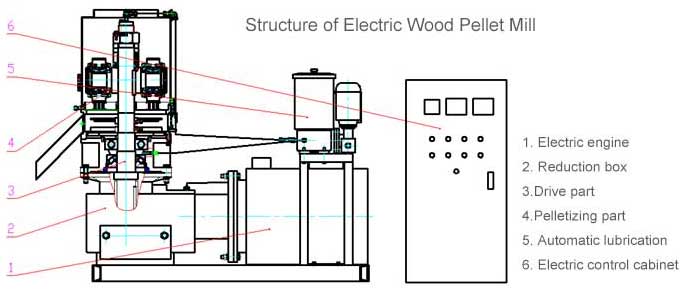

Structure of Wood Pellet Mill for Home Use

As it is mentioned above, this wood pellets making machine for home use has 3 driving forces: electric, diesel and PTO. The structures of this wood pellets maker with different driving engines are as follows:

Raw Material for Making Pellets with Small Wood Pellet Mill

This small wood pellet mill is flat die designed and is able to make pellets from both hardwood and softwood. Due to its small size and light weight, this wood pellets making machine is widely used at home or on farm for individual usages. This household wood pellet pressusually makes pellets from twigs, trunks, sawmill waste, forest harvest residuals for the bulk of their fibre supply, tree barks, sawdust, rice husks, peanut shells and all the other common biomass resources.

Wood Pellets

Wood pellets are a kind of biomass energy. Wood pellets are mainly made from wood waste, such as: wood sahvings, sawdust, wood chips and other by products of the manufacturers of lumber, furniture and other forest products.

With the development of economy and global expansion, the demand for more energy is ingradually increasing, and wood pellets as a new green energy is included.The major wood pellet-producing countries in North America and Europe are Canada, Germany, Sweden, and the United States. The major consumer countries for wood pellets are Belgium, Denmark, the Netherlands, Sweden, and the United States. The major wood pellet importing countries are Belgium, Denmark,the Netherlands, and Sweden. The United States produces a large quantity of wood pellets but also consumes a large quantity. In the United States, the Pellet Fuel Institute has designed a set of standards for wood pellet fuel grading.

| Fuel property | Premium grade | Standard grade | Utility grade |

|---|---|---|---|

| Bulk density | 40.0–46.0 | 38.0–46.0 | 38.0–46.0 |

| Diameter (inches) | 0.230–0.285 | 0.230–0.285 | 0.230–0.285 |

| Diameter (mm) | 5.84–7.25 | 5.84–7.25 | 5.84–7.25 |

|

Pellet durability index

|

≥96.5 | ≥95.0 | ≥95.0 |

| Fines (percent at mill gate) | ≤1.0 | ≤1.00 | ≤1.00 |

| Inorganic ash percentage | ≤1.0 | ≤2.00 | ≤6.0 |

| Length (percentage > 1.5 inches) | ≤1.0 | ≤1.0 | ≤1.0 |

| Moisture percentage (wet basis) | ≤6.0 | ≤10.0 | ≤10.0 |

| Chloride (parts per million) | ≤300 | ≤300 | ≤300 |

In contrast to the United States, where most wood pellets are used for residential heating with pellet stoves, a majority of the wood pellets in Asia are used for co-firing at coal-fired power plants. The Asia's major wood pellet markets are in China, Japan and South Korea.

If you are also interested in making wood pellets, you can know all the details about making wood pellets here.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!