Biomass power generation process and technology

What is biomass power generation?

Biomass power generation means to generate power with biomass fuel, including forestry and agriculture waste, garbage, landfill gas and biogas. Usually, there are direct-fired power generation and gasification power generation 2 ways.

Direct-fired power generation

In terms of biomass direct-fired power generation, it use crop straw and forestry waste as raw materials. After molding process, they are fed into the biomass boiler and burns sufficiently to generate steams. The steam drive the turbo-generator. The ash residues are processed into potash fertilizer and used on the farm. This technology upgrade the agriculture industry into a circular industrial chain. It is an ecological economy that turn waste into wealth.

Gasification power generation

In terms of biomass gasification power generation, it uses gasifiers to turn biomass into combustible gas. After a series purifying process of dedusting and decoking, the gas drive the internal combustion engine and gas turbine to generate power. It can be divided into biomass gasification, gas purifying and gas power generation 3 steps. Biomass gasification power generation can solve the organic waste pollution and make full use of renewable energy. Nowadays, biomass gasification has more and more researches and applications.

Biomass gasification plant

The process of biomass power generation

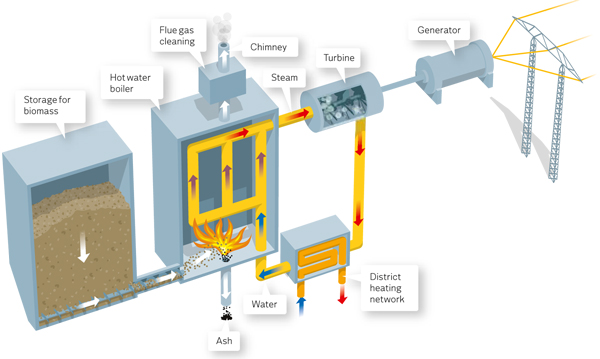

Biomass power generation is to convert the chemical energy of fuel into electricity. The complete conversion process is: chemical energy—thermal potential energy of steam—mechanical power—electric power.

The 3 major devices are boiler, steam turbine and electricity generator. In the boiler, the chemical energy of biomass fuel transforms into the thermal energy of steam. In the steam turbine, the thermal energy transforms into the mechanical power of turbines. In the generator, the mechanical power transforms into electricity.

Circulation of air and ash

The air is sucked into the air preheater by the force draft fan. Some of the hot air is sent to the feed bin for drying and conveying feed powder, some are sent to the hearth for combustion. The generated hot smoke go through the U shape flue under the suction of draft fan, and transmit heat to the working media and air. After purification by the deduster, the smoke is expelled to the air.

The heavy ash residues will fall to the hopper at the bottom of the hearth and become solid slag, and the discharge device expel them to the ash trench. Meanwhile, the smoke bring along the fly ash, and the deduster separate it out and send it to the ash trench.

Circulation of main steam and condensate

The water is transmitted to the economizer, which heat it up to near saturation temperature. Then the evaporator heat up the hot water and turn it into saturated vapor. Next, the heaters turn it into superheated steam, also called main steam.

The main steam go through the pipe and turns the steam turbine, which bring along the electricity generator. The waste steam from the steam turbine are sent into the condenser, where they transform into water. It is called main condensate. The main condensate is pumped into the low-pressure heater. Some of the condensate is extracted by the steam turbine, others are sent to the deaerator to remove the oxygen dissolved in water.

The pre-processed make-up water will mix with the main condensate in the deaerator. They are pumped to the higher-pressure heater. The steam turbine extract some steam for heating and send it to the boiler. This forms a thermodynamic circle. The circulating water pump send the cool water to the condenser, and form a recirculating cooling water system.

The processes above includes the transmission and burning of fuel, the treatment and discharge of ash, slag and smoke, the transformation from thermal energy to mechanical energy and electricity, and the circulation of make-up water. The whole process is accomplished by the correlation of the boiler, steam turbine and electric motor.

3 biomass power generation technology

Direct-fired power generation

The biomass fuels are fed to an specialized boiler and generate steams, the stems expand and drive the generator. Biomass direct firing will remain as the major application form of biomass energy. The main task is to improve the energy conversion efficiency.

Thermo-chemical conversion technology

Thermo-chemical conversion refers to the gasification, carbonization, pyrolysis and liquefaction of biomass under a certain temperature. Then use the gas, liquid and solid fuels to generate electricity.

Bio-chemical conversion technology

Bio-chemical conversion includes the transformation from biomass to biogas, and from biomass to ethanol. Biogas is a mixed combustible gas generated by organic matters in anaerobic environment. Ethanol is fermented by sugar, starch and cellulose. The steam turbine and reciprocating engine use biogas and ethanol as fuel and drive the power generator.

The development of biomass power generation

Biomass power generation originate in the 1970s, when the oil crisis broke out all over the world. Demark started developing renewable energy, and promoting biomass power generation. Since 1990, biomass power generation start rapid development in many Europe and America countries.

The research and development of biomass pyrolysis gasification technology is in progress in many countries. Finland Dan Pere power company has developed a waste wood gasification power plant in Sweden. Sweden energy center plan to build a power plant in Brazil that use gasification and joint cycling power generation to make use of local bagasse resources. American has more than 350 biomass power plant. The biomass pellet fuels developed in the 1970s has been widely applied in America, Canada, and Japan.

Biomass power plant

The significance of biomass power generation

The adoption of biomass power can alleviate the crisis of energy shortage and lower the energy cost. Biomass power generation is a new industry, it can promote local development and increase income. Besides, it has another 2 benefits.

Reasonable dispose of agriculture waste

The raw material of biomass power plant are wheat, corn, and cotton straw, rice husk, wood processing wastes. Using them to generate power reduce open-air burning, save coal resource and increase farmers’ income.

Relieve environment pollution

Biomass fuels are a kind of renewable energy. They can replace some fossil fuels, and reduce the CO2 emission to the atmosphere. Meanwhile, the SO2, NO and smoke emission of biomass power plant is lower than coal. Many European countries provide subsidy to the biomass plant with the aim to reduce pollution emission. Policy support will promote the development of biomass power generation.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!