How to avoid pellet mill blockage?

In wood pellet production, the roller extrude the crushed raw materials to the holes on the die, and form them into cylindrical pellets. If you operate the pellet machine improperly, the raw materials would get blocked in the die. Here I’d like to introduce some method to prevent pellet mill blockage.

Don’t make pellets without running in process

If you didn’t have the running in process before making pellets, the pellet machine are easy to get blocked.

Solution: Every time before starting making pellets, feed the pellet machine with the mixture of sawdust and 10% engine oil. Then put the produced wood pellets back to the pellet machine for 5-6 times. After that, you can feed normal sawdust to make pellets.

The roller get loose

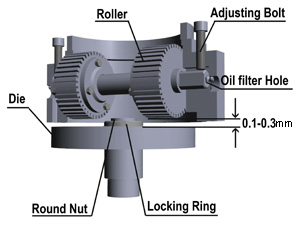

The roller is the core component in the compression chamber. It keep on rotating to extrude the materials out through the holes on the die. If the roller get loose, it will have larger clearance with the die. The pressure will decrease, and the raw materials will pile in the die.

Solution: stop the machine and check. Adjust the clearance between roller and die.

Low voltage of the electric motor

The electric motor can work normally under rated voltage. Under low voltage, the motor cannot generate enough power to extrude out all the raw materials. There will be large quantities of raw materials get blocked in the compression chamber.

Solution: Add a switching room or a transformer to stabilize the voltage.

The die holes are blocked by impurities

In pellet machine production, the blockage of die holes will impede the extrusion of materials. And the raw materials will stop up in the compression chamber.

Solution: stop the machine, open up the stock bin, clear up the raw materials, and take out the die. Grind the hole of the die carefully with professional tools. Avoid any abrasion and damage to the die.

The main bearing break down

The damage of bearing will disable the compression components, and make large quantity of materials blocked in the compression chamber.

Solution: lubricate the bearing regularly. If the bearings have worn out, you can replace it with a high-quality one.

How to unclog the pellet mill die?

If you operate the pellet machine improperly, the pellet mill die will easy to block. Usually, people use electric drill to drill the materials out. This method takes up too much time and damage the surface of the holes.

Boil the ring die with oil. First, fill a iron oil pan with waste engine oil. Then, put the blocked die in the oil pan, and immerse it in the oil. Next, heat up the oil pan until the raw materials in the die crack. Finally, cool down the die, install it again, and adjust the roller and die clearance. With these steps , you remove the materials in the die quickly without damage the surface.

Besides pellet machine blockage, wood crusher are possible to block up if you operate it in wrong way.

How to solve the wood crusher block up

If the discharge pipe is not smooth, or the feeding speed is to high, the air vent of the wood crusher will block up. If the feed conveyor doesn’t match well with the wood crusher, the wind in the discharge pipe will weaken and the pipe will block up as the wind gradually fade away.

Solution: clear up the air vent, replace the unmatched feed conveyor, adjust the feed volume.

The hammers age or break off. The screen holes block or break.

Solution: replace the aging or broken hammers, inspect the screener regularly.

The water content in the raw materials are too high.

Solution: the water content of raw materials should be under 14%. This can improve the production efficiency and prevent blockage of the hammer mill.

Over-high feeding speed will cause blockage and overload of electric motor. Long-time overload will cause motor burnout.

Solution: Turn down or close the feed port. Control the feeding speed by adding an automatic feeder. As the wood crusher has high rotating speed and high-volatility load, the working current is usually 85% of the rated current.

We receive enquiries in English, Español (Spanish), Русский язык (Russian), Français (French) and العربية (Arabic). Our professional team will reply to you within one business day. Please feel free to contact us!